A living reference material for producing monoclonal antibodies

Since 2016, manufacturers of monoclonal antibodies (mAbs) have been able to verify and improve their quality control methods by using a reference material from the US National Institute of Standards and Technology (NIST), called NISTmAb. NIST has now developed a new line of mAb-producing living cells that can help manufacturers better understand how their mAb drugs can be affected during the production process, to further ensure they are producing pharmaceuticals that work as intended.

Monoclonal antibodies — proteins that can bind to specific targets in the body — can fight everything from cancer and rheumatoid arthritis to COVID-19. NIST researchers, in collaboration with MilliporeSigma and the National Institute for Innovation in Manufacturing Biopharmaceuticals (NIIMBL), have developed a new cell line, called NISTCHO, which produces a mAb molecule that is highly similar to the NISTmAb reference material. Derived from the same Chinese hamster ovary (CHO) cells that are predominantly used by industry for mAb biomanufacturing, the cell line is now available for use in the research community as NIST Research Grade Test Material 10197.

The original NIST Monoclonal Antibody Reference Material 8671 has become a widely used standard for studying and measuring the properties of other mAb proteins. However, researchers cannot easily modify certain properties and characteristics of NISTmAb, limiting the experiments and R&D they can do with it. This is where the new NISTCHO test material comes in.

“NIST and the biomanufacturing community have spent the last eight years or so developing and studying NISTmAb as a fixed starting point to develop new ways to measure monoclonal antibodies, how to standardise those measurements and how to measure changes in monoclonal antibodies caused by stress and/or storage conditions,” said NIST biologist Zvi Kelman, noting that every one of those studies started with exactly the same NIST reference protein molecule. NISTCHO contains genetic instructions for producing NISTmAb, but the end product is not the same exact material.

“NISTCHO will allow researchers to test changes in a monoclonal antibody that result from the biology in play when the CHO cells produce the molecule, as well as how a monoclonal antibody’s properties are influenced by things that happen later such as purification and storage,” Kelman said.

In addition, NISTCHO can also be used to benchmark the performance of new biomanufacturing technologies. For example, a company might develop a new kind of bioreactor or cell culture media and use NISTCHO to demonstrate an increase in the amount of NISTmAb that’s produced by NISTCHO through these methods, said Michael Tarlov, Director of the NIST Biomanufacturing Program.

NIST makes various kinds of reference materials, each of which undergoes differing levels of review and measurement procedures. NISTCHO currently is considered a NIST research-grade test material (RGTM). RGTMs provide an opportunity for NIST researchers to collaborate with scientists from the research community to work on the material and compare results as well as obtain feedback. The goal of an RGTM is to evaluate the material’s match to its intended purpose and, depending on feedback and further studies from the research community, motivate the development of a reference material.

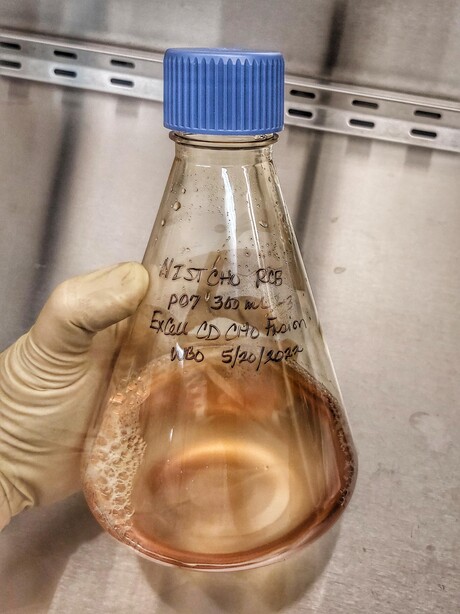

To make the RGTM, NIST researchers first gained access to the NISTCHO cells through a partnership with MilliporeSigma, a commercial supplier of biotech products. They then performed a well-established process to manufacture NISTCHO cells into the RGTM. The process, known as cell banking, involves growing trillions of cells, transferring them to vials while maintaining sterility and freezing them carefully so they remain viable for future use. NIIMBL, a Manufacturing USA institute sponsored by NIST, helped coordinate efforts between NIST and MilliporeSigma to develop NISTCHO — a first-of-its-kind NIST living reference material that will be available to researchers worldwide.

“Typically, antibody-producing cell lines that are most like those used for large-scale, clinical manufacturing aren’t available for open-access research due to the intellectual property that’s invested,” said NIST biologist Brad O’Dell. “This means that many researchers can’t access a cell line that is representative of those used by industry. NISTCHO will change that. MilliporeSigma and NIIMBL have helped NIST to develop NISTCHO for the express purpose of making these industry-grade mAb producing cells publicly available.”

The next phase in the project is to develop a NISTCHO reference material (RM) using both the knowledge gained from the NISTCHO RGTM and NIST’s measurement science capabilities and expertise. A NISTCHO RM will require careful measurement of NISTCHO and determining specific properties or values, like a DNA sequence or a molecule’s concentration, that NIST can confidently report along with a description of potential sources of error or uncertainty. With those added measurements, the NISTCHO RM could support calibration and standardisation in addition to basic and applied R&D.

Antimicrobial coating for sanitary fabrics inspired by mussels

The innovative material fights against the spread of pathogens and antimicrobial resistance,...

Staying compliant: how lab scrubs meet industry regulations and standards

Australian companies involved in any lab work have to see to it that their lab scrubs meet...

NIST reference materials to help combat seafood fraud

The new reference materials can help food inspectors assess the authenticity of seafood, which...