New catalyst enhances efficiency of ammonia conversion

Scientists from Hokkaido University and the University of Technology Sydney (UTS) have led the development of a new catalyst with the remarkable ability to enhance the efficiency of ammonia conversion, which could improve wastewater treatment as well as green chemical and hydrogen production. Their work has been published in the journal Advanced Energy Materials.

Ammonia can cause severe environmental problems, such as excessive algal growth in water bodies, which depletes oxygen and harms aquatic life. At high concentrations, ammonia can harm humans and wildlife. Effective management and conversion of ammonia are thus critical, but its corrosive nature makes it difficult to handle.

Catalysts, meanwhile, are substances that speed up chemical reactions by providing a more efficient route for a reaction to occur and making it easier to start and finish. Since catalysts are neither consumed nor altered in the reaction, they can be used repeatedly, and they are essential in a variety of industrial, environmental and biochemical processes.

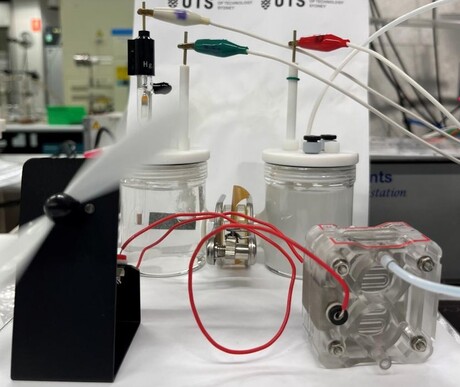

The research team developed their catalyst, called NiOOH-Ni, by combining nickel with nickel oxyhydroxide via an electrochemical process. Nickel foam, a porous material, was treated with an electrical current while immersed in a chemical solution. This treatment resulted in the formation of nickel oxyhydroxide particles on the foam’s surface. Despite their irregular and non-crystalline structure, these nickel-oxygen particles significantly enhance ammonia conversion efficiency. The catalyst’s design allows it to operate effectively at lower voltages and higher currents than traditional catalysts.

“NiOOH-Ni works better than nickel foam, and the reaction pathway depends on the amount of electricity (voltage) used,” explained UTS Professor Zhenguo Huang, who led the study. “At lower voltages, NiOOH-Ni produces nitrite, while at higher voltages, it generates nitrate.”

This means the catalyst can be used in different ways depending on what is needed. For example, it can be used to clean wastewater by converting ammonia into less harmful substances. But in another process, it can also be used to produce hydrogen gas, a clean fuel. This flexibility makes NiOOH-Ni valuable for various applications, while its long-term reliability makes it suitable for large-scale industrial use.

“NiOOH-Ni is impressively durable and stable, and it works well even after being used multiple times,” said Associate Professor Andrey Lyalin, from Hokkaido University. “This makes it a great alternative to traditional, more expensive catalysts like platinum, which aren’t as effective at converting ammonia.”

Antibody treatment reprograms immune system after heart attack

A new drug being trialled in heart attack patients could reprogram the immune system to prevent...

Nanoparticles supercharge vinegar's wound-healing power

Adding microscopic particles to vinegar can make them more effective against dangerous bacterial...

Not all brown snake venoms are alike, causing antivenom concerns

Venom from northern and southern populations of eastern brown snake builds blood clots in very...