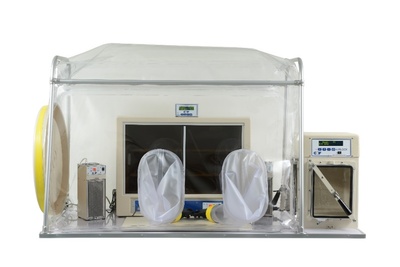

Coy Anaerobic Chambers

Used for over 40 years in anaerobic microbiology research, these units are also critical to many other research areas such as protein purification, clinical microbiology, biochemistry, cell culture, human microbiome studies, biofules and more.

Coy Anaerobic Chambers eliminate oxygen to 0–5 parts per million (ppm) using a hydrogen gas mix (5% or less) reacting with a palladium catalyst to remove oxygen by forming a water molecule. A vacuum airlock is used to reduce oxygen levels prior to transfer of samples and tools in and out of the glove box. Access ports allow sample manipulation without ever exposing your samples to ambient conditions.

Temperature incubation options include heating the entire glove box to be your incubator or placing a specially designed Coy incubator within the workstation interior for a more comfortable working atmosphere for the users. Large Ports are included for large equipment transfer and smaller feed-thru ports available on every unit to pass cords/tubing in and out of the chamber in a sealed fashion.

The Coy Vinyl Anaerobic Chamber is the most cited chamber in the world for anaerobic microbiology because it is the strictest anaerobic system on the market and the most efficient with regards to gas consumption. The vinyl expands and contracts to allow for changes in internal pressure without expelling the expensive gas mix to room atmosphere, saving you up to 60% on your operational gas cost annually.

The large oval glove ports allow all user to reach deeper and higher into the chamber for greater storage capacity and ergonomics. This allows a vinyl unit to be manufactured larger than other rigid style units which in turn makes it easier to maintain the anaerobic chamber conditions and helps create a stricter control of the anaerobic conditions.

Vacuum Airlocks (Pass Thru)

Coy vacuum airlocks remove O2 from ambient conditions to achieve acceptable levels of O2 prior to transfer to/from the chamber. The airlock reaches the low O2 level through a multiple vacuum/purge procedure. Automatic airlocks are equipped with an advanced electronic program that allows adjustments in vacuum levels, number of cycles, calibration of pressure sensors, and programmable profiles, depending on the type of work being done in the chamber. All vacuum pumps are equipped with moisture traps to prevent excess moisture from the chamber or gas tanks from entering the pump. Automatic airlocks operate with the touch of a button.

Anaerobic Monitor (CAM-12)

The Coy CAM-12 is the only analyzer that offers both O2 (PPM) and H2 (%) monitoring in within one unit.

- Detects real-time transient level changes

- Adjustable alarm levels

- User replaceable sensors

The CAM-12 Analyzer has been successfully used by researchers to monitor levels of oxygen and hydrogen in their anaerobic chambers for over 25 years. Your anaerobic chamber becomes a dynamic environment in which you can readily determine leaks, bad catalyst or a need for change in equipment layout or airlock procedure. The H2 monitor allows each lab to optimize their Gas Mix consumption rate saving time and operational cost.

Anaerobic Gas Infuser

Optimize your anaerobic gas consumption and save on operational cost with the Coy Anaerobic Gas Infuser. The Gas Infuser operates with the Coy Anaerobic Monitor to ensure proper H2 levels are maintained at all times, saving your lab time and money by doing this automatically and ensuring your anaerobic workstation only uses the proper amount of H2 content.

The Anaerobic Gas Infuser also includes data logging software allowing you to chronicle your oxygen and hydrogen levels. Tracking this data is ideal for troubleshooting, minimizing waste and improving lab efficiency.

Atmosphere Filter System

This recirculating system will control contamination of particles 0.3 microns and larger. Engineered much like the dehumidification apparatus, the filter receives glove box atmosphere drawn by a vacuum pump and returned to the glove box. The filter sits outside the glove box and can be changed without compromising the integrity of the glove box’s seal.

Recirculating Atmosphere Filtration System (HEPA)

This system filters the box atmosphere and controls contamination through a standard HEPA filter. The external pump-activated system has the filter mounted outside the box. The system draws the internal atmosphere out of the box, through the external filter and back into the box. Equipped with sealed quick-disconnect fittings, the filter is fast and easy to change without compromising filter and glove box integrity.

Moisture Control for Anaerobic Chambers

Controlling moisture within an anaerobic chamber is one of the most important aspects but each chamber is different.

Moisture enters the chamber in several ways:

- Gas Supply Tank

- Ambient Moisture in the airlock transfer process

- Media stored in the chamber (liquid vs solid media)

- Moisture producing material or equipment inside the chamber

- The catalytic reaction during the O2 removal process

To remove moisture from the chamber Coy Labs offers you the following two methods: Alumina Desiccant contained within a Stak-Pak and combined with the Stak-Pak catalyst; or a Large Capacity Dehumidifier that fits into the large equipment entry port.

Desiccant Stak-Paks are an inexpensive way to deal with minor moisture issues. However for moderate to severe moisture the Large Capacity Dehumidifier is the most effective choice.

Forced Air Incubator for Vinyl Chambers

This incubator is custom-engineered to create a constant-temperature environment in vinyl chambers and offers sliding doors. There is no wasted space in front of the incubator for door clearance. Uniform heating results from forced air being drawn horizontally across the inside face of the door panels and from around the incubator’s outer shell. Solid-state electronics allow precise monitoring and control of heat output. A bright LED digital display provides a readout of the incubator’s actual mean temperature and allows the operator to set the desired temperature. The Model 2000 is available in a standard unit with a temperature range of up to 40°C or in a higher-range unit up to 65°C. The incubator maintains a uniform temperature with a maximum deviation of ±1°C from the set point. It has a capacity of 350 standard (100 mm) petri dishes.

Interview: Revolutionizing Global Vaccine Shipments with Releye

In the world of pharmaceutical logistics, adopting new technologies and innovative solutions is...

Life Science and Laboratory Decontamination

Decontamination should be considered multiple times through the life cycle of your laboratory.

Not All Biosafety Cabinets Are Created Equally

Brand new to the market, the Thermo Scientific Herasafe 2025 model adheres to what Peter Bigelow...