Compressed air in the pharmaceutical industry: part 1

The extensive automation characteristic of modern production methods in the pharmaceutical industry makes compressed air a vitally important energy carrier. Supply failure can result in expensive downtime, whilst inefficiencies in production and distribution can mean unnecessarily high costs.

This two-part series from Kaeser Compressors illuminates design and implementation principles for ensuring an efficient, reliable and cost-effective compressed air supply — which is often possible without major effort.

Introduction

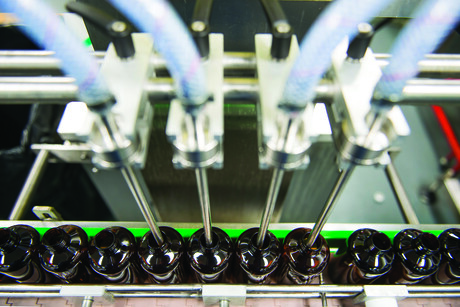

Compressed air is used widely throughout the pharmaceutical industry, from processes and transport of pharmaceutical materials through to packaging and use in medical devices. The huge variety of different requirements and individual design options characteristic of each production operation makes it impossible to make a one-size-fits-all final recommendation.

Major differences are evident simply in the floor plans and usage of space: different production sites are distributed over large areas, some housed in one or more buildings, whilst others may be meticulously planned in advance or the result of organic growth over time. Yet all share one commonality: an individual approach must be taken in each case.

This plethora of possible differences results in each case having widely differing weak points and cost drivers (Figure 1). Thanks to some basic criteria, however, reviewing and even improving one’s own system is easy to accomplish. When produced under unfavourable conditions, compressed air can be very expensive; yet when the right framework is provided, compressed air can be extremely cost-effective.

Energy consumption and cost analysis, cost planning and ongoing management, as well as permanent optimisation based on actual circumstances, are all indispensable to any cost-effective and reliable system. Innovative products and services recently launched on the market significantly facilitate the realisation of these key features whilst also ensuring that the compressed air supply is capable of accommodating future developments — provided several key points are taken into account.

Analysis: the first step

Although the ideal situation is to plan a completely new compressed air supply from the ground up, it’s more common for existing systems to be assessed and optimised where possible. In either case, nothing meaningful can be accomplished until an air demand analysis has been performed — and this often presents the first stumbling block. Despite the significant progress achieved in compressed air technology in recent years, only a fraction of compressed air system operators actually know this crucial value in relation to their own system.

In a ‘mature’, running pharmaceutical operation, compressed air often remains a process element that’s simply ‘just there’ and doesn’t necessarily garner any further attention. Yet it’s precisely companies that have grown over time whose compressed air systems often harbour dramatic potential cost savings. These savings can be achieved in several different areas:

- Optimal adaptation and layout of the compressed air system based on the company’s actual needs.

- Energy cost reductions through the use of low-consumption, highly efficient components.

- Optimisation of monitoring and service provision over the entire life cycle of the compressed air system.

Today, any business planning a new compressed air supply or renovating its existing one absolutely has to have the overall concept in mind, as well as the system’s continuing viability into the future.

Compressed air systems have a long average service life of some 20 years and are often used every single day. Some investments that may appear attractive over the short term can turn out to be very expensive in the long run. On the other hand, higher initial investment often pays for itself rapidly, then goes on to yield cost advantages year after year.

As a general rule, relatively high potential savings can be achieved through optimisation of compressed air systems. According to studies, savings ranging between 10 and 70% of energy costs can be achieved — regardless of the condition of the existing system (Figure 2).

A compressed air system comprises more than just the station itself; it’s rather like a chain, as in the case of electricity generation. In relation to compressed air, the chain begins with compressed air production, followed by treatment and distribution, and ends with the compressed air user. The whole chain must work synergistically to achieve the most cost-effective compressed air supply (Figure 3).

Since in most cases the compressed air required in the pharmaceutical industry must be highly pure, achieving synergies becomes especially important in this sector in particular, since compressed air loss or potential contamination can occur at all points along the chain. There’s no point in having the compressed air station produce top-quality compressed air unless this high quality level can be maintained throughout the downstream distribution network and by the end consumer. Ideally, optimised production, appropriate treatment, suitable distribution and constant monitoring go hand in hand.

The compressed air system ‘chain’

When planning or renovating a compressed air system, the first step is to answer some fundamental questions. How high is the air demand? What pressure is required? What processes will the compressed air be used for and what are the compressed air quality requirements of these processes? Are there some processes in which the waste heat from the compressors can be reused?

To determine the answers, the system is closely examined in great detail, from all angles. First the pressures, flow rates and compressed air quality of the consumers are determined; next it’s determined whether there is a decentralised treatment system. Finally, the pipelines are considered in terms of their length, diameters and materials.

When it comes to centralised treatment, the required compressed air quality levels play a role, along with ambient conditions, including temperature, inlet pressure, inlet temperature and inlet moisture.

Following treatment, it’s time to consider the compressors. What type of compressor is involved and, if applicable, how is splitting implemented amongst the compressors? These are just a few of the important questions that have to be asked.

In order to ensure optimal efficiency of the compressed air supply, the system controller is absolutely critical. For larger stations, the ideal solution is a master control system that controls the entire station with maximum efficiency whilst also enabling modern energy management, data analysis and remote servicing, including predictive maintenance. In any case, the compressors themselves should be equipped with a controller that supports integration options. When the entire system is taken into consideration, potential leaks also play a major role in the analysis.

The second part of this series examines these topics in detail and provides specific action recommendations to effectively achieve energy efficiency improvements.

Best practices for safe centrifugation in the laboratory

The majority of all centrifuge accidents are understood to result from user error. These tips...

Nature-inspired filtration system recovers critical resources

A filtration system that can recover untapped critical resources such as copper and lithium from...

Optimising food and beverage testing with laboratory equipment

In the food and beverage industry, laboratories must balance precision, speed and compliance to...