Novel adhesive is strong, smart and reusable

Scientists from Nanyang Technological University, Singapore (NTU Singapore) have developed a smart, reusable adhesive more than 10 times stronger than a gecko’s feet adhesion, opening the way for reusable superglue and grippers capable of holding heavy weights across rough and smooth surfaces. The team found a way to maximise the adhesion of the material by using shape-memory polymers, which can stick and detach easily when needed simply by heating them. Their work has been described in the journal National Science Review.

Shape-memory polymers are materials that can hold ‘memories’ of their previous form and return to their original shape after they have been deformed by applying external stimuli such as heat, light or electrical current. These properties make them ideal to be used as switchable adhesives that can adapt to various surfaces.

In their testing, the researchers used a shape-memory polymer named E44 epoxy, a stiff and glass-like plastic at room temperature. Upon heating, the material turns into a soft rubber-like state that can conform and lock onto microscopic nooks and crevices. As it cools, it becomes glassy, creating extra-strong adhesive bonds due to a shape-locking effect. When the material is reheated, it reverts to its rubbery state so it can be pulled away and easily detached from the surface it was clinging to.

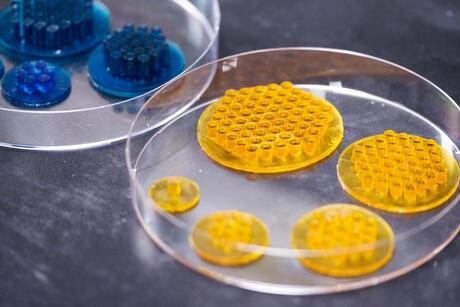

The researchers found that the most effective adhesion came from designing the shape-memory polymer into an array of hair-like fibrils. Each fibril had to be carefully designed — larger fibrils had weaker adhesion, while the smaller fibrils were hard to fabricate and prone to collapse and degradation. The sweet spot was between 0.5 and 3 mm in radius, pushing the limits of adhesion while retaining structural integrity.

In their experiments, the researchers found that one fibril with a 19.6 mm2 cross-section could support loads up to 1.56 kg. Every additional fibril allows for more weight to be supported. A palm-sized array of 37 fibrils weighing about 30 g can hold a weight of 60 kg — an adult human’s weight.

“Our smart adhesive exemplifies how shape-memory polymers can maintain and even enhance adhesion as surface roughness increases,” said Dr Linghu Changhong, the paper’s first author. “This overcomes the ‘adhesion paradox’, which scientists have been puzzling over, where there is a decrease in adhesion strength on rough surfaces despite having more surface area for molecules to adhere to. Our tests showed that adhesion strength of the polymer increases along with surface roughness when in a solid state and decreases when in the rubbery state.”

Co-corresponding author Professor Gao Huajian, currently based at Tsinghua University, added, “Stronger adhesives can support heavier loading but tend to be harder to detach — this is what we call a ‘switchability conflict’. Our research into shape-memory polymers has resulted in an adhesive that can easily harden to stick onto surfaces, and just as easily soften to detach, all the while being able to bear heavy weights including that of a human being.

“The shape-memory polymer adhesives we designed overcome both the adhesion paradox and the switchability conflict, providing guidelines for developing stronger and more switchable adhesives adaptable to rough surfaces.”

Detaching the shape-memory polymer while it is attached to a surface in a glass state takes less than a minute of heating using a hair dryer to bring temperatures up to 60°C. For attachment, it takes about three minutes for the material to cool down thoroughly and lock into place. The temperature at which the polymer changes states can be controlled by adjusting the ratios of the components used to form the polymer, which allows the polymer to be used in extreme environments such as hot weather conditions.

“At this current stage, the heating and cooling times, as well as switching temperature, restrict the number of real-world use cases,” Changhong said. “However, our findings show that reducing the wait times to mere seconds is possible, and the switching temperatures can be lowered to near body temperature, dramatically opening up application possibilities.

“The stimuli to switch the material from one state to another can also be different, such as using electrical current or light instead.”

The ability of the material to attach and detach using only heat lets it act as a reusable superglue that does not leave behind sticky residue on walls. And given its ability to support heavy weights, the adhesive could in future be deployed in climbing equipment that allows humans to scale walls effortlessly, or robots that can cling onto ceilings for survey or repair applications.

“This research is based on a fundamental understanding of the mechanisms of adhesion forces on rough surfaces,” said research team leader Professor K Jimmy Hsia. “It can help us develop very strong, yet easily detachable, adhesives adaptable to rough surfaces. The technology will be very useful in adhesive grippers and climbing robots and might one day let humans climb walls like a real-life Spider-Man.”

Best practices for safe centrifugation in the laboratory

The majority of all centrifuge accidents are understood to result from user error. These tips...

Nature-inspired filtration system recovers critical resources

A filtration system that can recover untapped critical resources such as copper and lithium from...

Optimising food and beverage testing with laboratory equipment

In the food and beverage industry, laboratories must balance precision, speed and compliance to...