Brisbane startup tests rocket thruster valve in space

Brisbane startup company Valiant Space, which has been supported by the Queensland Government’s Advanced Robotics for Manufacturing (ARM) Hub, has sent a component from its new rocket thruster into orbit, onboard a SpaceX mission that was launched this month from the Kennedy Space Center at Cape Canaveral.

Valiant Space co-founder and CEO Andrew Uscinski said one of the challenges for new businesses in the space industry was the need to validate your product by successfully launching it into space.

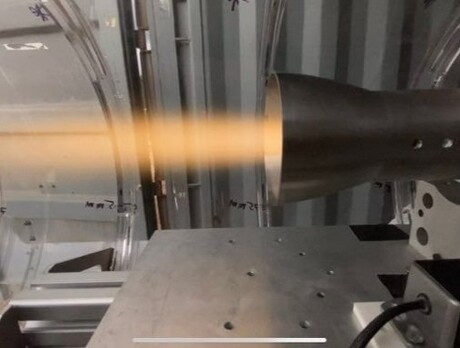

“We’ve developed Australia’s first in-space chemical thruster for satellites made with non-toxic propellants, and right now our focus is proving it can withstand orbit,” Uscinski said. The first step in this validation process will occur on a valve that is an integral part of Valiant’s thruster, which was sent into orbit with SpaceX on board Australian space services company Skykraft’s rideshare service.

Once the valve has demonstrated it can survive a violent launch, 6g gravitational force, extreme vibrations and a wide range of temperatures on its journey into space, Valiant Space’s full thruster will be launched on a subsequent orbital mission in mid-2023.

Valiant’s young team of three — consisting of Uscinski, fellow co-founder and Chief Technical Officer Michael Douw and lead engineer Benjamin Dodd — are mechanical and aerospace engineers who met at The University of Queensland and started their company while they were students. The three are keen pilots who identified a gap in the market for space propulsion options that used non-toxic propellants.

“Existing options are made from very carcinogenic and difficult-to-handle chemicals, which makes them very expensive because of all the development costs,” Uscinski said.

“Our thruster runs on nitrous oxide and propane — like what you would use in a barbecue, but slightly more pure — which gives a comparable performance to the toxic options, but without the need for high-cost handling infrastructure.

“Our solutions will save money at every step of the mission life cycle, by leveraging a simplified design, rapid manufacturing methods and low-cost propellants.”

3D-printed and almost entirely Australian made, the thruster is mounted on the spacecraft to provide the main propulsion system for the satellite and enables companies to perform fast-acting orbit raising and collision avoidance manoeuvres. “It means satellites can come online quickly, and they stay in their optimal orbit and last longer in space,” Uscinski said.

“We build the thrusters to begin with and then, when we work with a satellite company, we help them design the rest of the components — like fuel tanks and oxygen tanks.”

The Valiant Space team started their operation at the Advanced Robotics for Manufacturing (ARM) Hub workshop in Northgate, Brisbane, in November 2020. Uscinski stated, “ARM Hub offered us flexibility in leasing, which is fantastic for startups, and they have such a large warehouse that has allowed us to expand out as needed.

“They’ve also helped us gain exposure to a variety of people, including potential investors and Ministers and MPs.”

Valiant Space recently secured $750,000 funding from the Australian Government’s Moon to Mars Initiative supply chain grant, administered by the Australian Space Agency. The team previously won a Moon to Mars Initiative demonstrator feasibility grant in 2021, to mature their non-toxic thruster technology.

“The staff at ARM Hub have helped enormously by identifying funding opportunities and helping us write our first successful Moon to Mars grant,” Uscinski said.

“The first grant helped us to prototype and test our product, which has been instrumental in gaining market traction and momentum.

“With this second grant, we will be getting flight validation on our product, build the supply chain and upscale our propulsion technologies to domestic and international customers.”

Please follow us and share on Twitter and Facebook. You can also subscribe for FREE to our weekly newsletters and bimonthly magazine.

Aerosol test for airborne bird flu developed

The low-cost sensor detects the virus at levels below an infectious dose and could lead to rapid...

Superelastic alloy functions in extreme temperatures

The titanium-aluminium superelastic alloy is not only lightweight but also strong, offering the...

Water-repellent glass breaks new ground

An innovative and non-toxic process using ultrasonic sound waves can alter the surface of glass,...