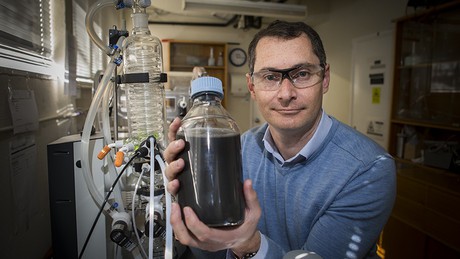

Graphene production using a designer surfactant

Australian scientists have developed a material based on graphene that has the heat resistance of some metals but is much lighter. It is also durable, chemical resistant and biocompatible, making it potentially suitable for a range of transport and medical applications.

Graphene is a form of carbon, made of layers a single atom thick, which has high electrical and heat conduction. Taking advantage of these properties at a large scale requires making composite materials that link many graphene sheets, which until now has required expensive and toxic solvents because graphene is not water soluble.

Now, researchers from The Australian National University (ANU) and Swinburne University of Technology have developed a way to produce graphene using a designer surfactant, a chemical that works similarly to the way soap dissolves grease in water. As well as suspending the graphene, the surfactant molecules were engineered to link together to form a polymer.

“Because the chemical we use to suspend the graphene becomes the matrix, it takes out a couple of steps and makes the manufacturing much quicker and easier,” said co-lead author Dr Tao Wang, from Swinburne’s Department of Chemistry and Biotechnology.

“Usually the surfactant is an intermediate chemical you have to get rid of before you cross-link the polymer, which is a headache. But ours is implicitly involved in forming the composite.”

The resulting material is stable at very high temperatures and features a “combination of strength and electrical properties as good as anyone’s made before”, according to co-lead researcher Associate Professor Shannon Notley from ANU.

“Our graphene is produced in a very low-cost way; it’s very scalable, it is defect-free, it is very thin sheets, and also is functionalised for end-user purpose,” he added.

The team has already demonstrated the new material’s potential for medical applications by growing a layer of mammalian cells on it. According to Associate Professor Notley, “This material’s ability to merge into the body will greatly improve outcomes for implants.

“It could also be crucial for the development of tiny sensors implanted in the body and could even be used for fuel cells based on bacterial interactions found in nature.”

Dr Wang said the new understanding of molecular mechanisms developed in this research, published in the journal Advanced Materials Interfaces, will enable scientists to tailor chemicals to get the properties they need.

“It’s a unique system; it’s opening up a whole new way of making nanocomposites,” he said.

'Optical tweezers' could help study living cells

Physicists are using the tweezers to measure activity within microscopic systems over timeframes...

Aerosol test for airborne bird flu developed

The low-cost sensor detects the virus at levels below an infectious dose and could lead to rapid...

Superelastic alloy functions in extreme temperatures

The titanium-aluminium superelastic alloy is not only lightweight but also strong, offering the...