Lab-on-a-chip achieves fast, efficient cell separation

Researchers at Hiroshima University and AFI Corporation have created a new way to sort living cells suspended in fluid, using an all-in-one operation on a lab-on-chip that requires only 30 minutes for the entire separation process.

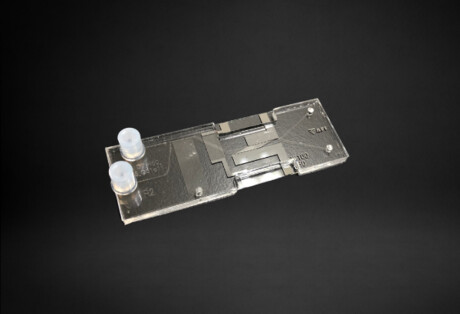

As described in the journal iScience, the researchers constructed a prototype of a microfluidic chip that uses electric fields to gently coax cells in one direction or another via dielectrophoresis — a phenomenon or movement of neutral particles when they are subjected to an external non-uniform electric field.

Dielectrophoresis induces the motion of suspended particles, such as cells, by applying a non-uniform electric field. Since the strength of dielectrophoretic force depends on the size of the cell and its dielectric properties, this technique can be used to selectively separate cells based on these differences. It could be particularly useful for medical research applications, its most significant advantage over other methods being its simplicity.

“In conventional cell separation methods such as commercially available cell sorters, cells are generally labelled with markers such as fluorescent substances or antibodies, and cells cannot be maintained in their original physical state,” said Professor Fumito Maruyama, lead researcher on the study. “Therefore, separating differently sized cells using microfluidic channels and dielectrophoresis has been studied as a potentially great method for separating cells without labelling.”

Prof Maruyama and his team introduced the separation of two types of eukaryotic cells with the developed microfluidic chip that used dielectrophoresis. Thanks to an all-in-one process, their device removed the need for labour-intensive sample pretreatment and chemical tagging techniques while preserving the original structure of the cells.

“The device eliminated sample pretreatment and established cell separation by all-in-one operation in a lab-on-chip, requiring only a small volume (0.5–1 mL) to enumerate the target cells and completing the entire separation process within 30 minutes,” Prof Maruyama said. “Such a rapid cell separation technique is in high demand by many researchers to promptly characterise the target cells.”

Common medical industry uses of cell separation include removing unwanted bacteria cells from donated blood and separating stem cells and their derivatives, which are crucial for developing stem cell therapies. Prof Maruyama noted, “If enrichment of a certain cell type from a solution of two or more cell types is needed, our dielectrophoresis-based system is an excellent option as it can simply enable a continuous pass-through of a large number of cells; the enriched cells are then easily collected from an outlet port.

“Dielectrophoresis cannot entirely replace existing separation methods such as centrifuge and polyester mesh filters. However, it opens the door to faster cell separation that may be useful in certain research and industrial areas, such as the preparation of cells for therapeutics, platelets and cancer-fighting.

“Future research may examine refinements, allowing us to use dielectrophoresis to target certain cell types with greater specificity.”

Please follow us and share on Twitter and Facebook. You can also subscribe for FREE to our weekly newsletters and bimonthly magazine.

'Optical tweezers' could help study living cells

Physicists are using the tweezers to measure activity within microscopic systems over timeframes...

Aerosol test for airborne bird flu developed

The low-cost sensor detects the virus at levels below an infectious dose and could lead to rapid...

Superelastic alloy functions in extreme temperatures

The titanium-aluminium superelastic alloy is not only lightweight but also strong, offering the...