Molecular Filtration in Life Science

Stringently controlled environments (cleanrooms) are necessary in maintaining effective air quality free from airborne contaminants within life science and pharmaceutical processes. While most HEPA air filtration systems focus on providing particulate-free air, it is worth considering that there are molecular, non-particulate contaminants that cannot be controlled via conventional particulate filtration technology.

Some of the most significant molecular contaminations involved within pharmaceutical processes include:

Chemical Vapour: Some substances used for medical production or in medical laboratories are in a liquid form and could produce critical vapour pressure. This means that the liquid turns into vapours to different extents at room temperature or during laboratory investigations.

Examples of liquids that may be harmful for personnel in a gaseous state include sulfuric acid (H2SO4), formaldehyde (CH2O), or ether (C4H10O). If inhaled, the harmful vapours can cause damage and in the most unfortunate case lead to death depending on the concentration. There are strict national and global rules & regulations for emission levels for certain critical contaminants, to ensure the protection and healthy work conditions for all personnel.

Odour: In pharmaceutical production, molecules and chemicals are used, sometimes intentionally for flavouring, and when used in high concentrations might cause strong odours. Some biopharma processes also release hydrogen disulphide (H2S) that has a very unpleasant smell which is also noticeable at very low concentrations.

Decontamination: When cleanroom processes have been compromised and have been exposed to contamination, it becomes necessary to decontaminate the cleanroom and equipment before restarting work. This involves sanitisation of the cleanroom and equipment with a cleaning agent in gaseous form such as hydrogen peroxide (H2O2), and due to the toxicity, gaseous concentration levels need to be reduced before the room can be used safely again by personnel. This can take several hours.

Additionally, ethylene oxide (C2H4O) is used to sterilize materials and instruments that cannot tolerate heat, moisture, or abrasive chemicals, such as bandages, sutures, surgical implements, syringes, endoscopes, devices with integrated electronics, devices with sensitive optics, etc.

Corrosion: The by-product of some life science production processes may emit corrosive gases. Hydrogen disulphide (H2S) is a corrosive gas that can corrode materials, especially electronic equipment used within production. A decontamination agent frequently used in life science applications is peracetic acid (C2H4O3) and this can be corrosive to certain materials.

Indoor contaminant sources and chemicals

A summary of indoor contaminant sources and chemicals within life science cleanroom environments may include:

| Chemical / Chemical Family | Indoor / Outdoor | Source |

|---|---|---|

| Ozone | Outdoor | Exhaust from vehicles, power plants, industrial boilers, refineries, chemical plants and other sources chemically react in the presence of sunlight |

| Nitrogen Dioxide | Outdoor | Vehicle exhaust, power generation |

| VOCs (Volatile Organic Compounds) | Indoor / Outdoor | Very diverse range of chemicals. Materials used in building construction and finishing, cleaning agents, cosmetics and perfumes, dry-cleaned clothes, flame retardant treatments, cafeterias odours |

| Aldehydes | Indoor / Outdoor | Vehicle emissions (diesel), industrial emissions, photochemical degradation of other atmospheric pollutants |

| Formaldehyde (the lightest aldehyde) | Indoor / Outdoor |

Hospitals (mortuary, pathology), pressed wood products, carpets, cigarette smoke |

| Styrene | Indoor | Plastic equipment used in IVF procedure and other plastics in the clinic |

| Peracetic acid | Indoor | Cleaning / decontaminating / sterilising agents used to treat processes and premises. In hospitals used to decontaminate endoscopy material |

| Hydrogen peroxide | Indoor | Cleaning / decontaminating / sterilising agents used to treat products, processes and premises |

| Ethelene Oxide | Indoor | Cleaning / sterilising agents used to treat products in medical device production, dental or veterinary clinics |

Molecular Filtration

Molecular or gaseous filtration is a common method of removing unwanted gases and vapours from the air, including volatile organic compounds (VOCs), ozone, aldehydes, formaldehydes, nitrogen oxide (NOx) and styrene molecules.

Activated carbon, impregnated activated carbon or activated alumina chemical blends are generally used to capture and remove these unwanted gases and vapours from the air using the process of adsorption. Common molecular filtration products use these activated carbon and chemical media blends embedded into filtration media to create panel or compact style molecular filters, or as loose pelleted media housed within different types of molecular filtration housings or cannisters.

Molecular filtration can support production challenges within life science and pharmaceutical processes, with the following benefits:

- Remove harmful vapours to improve air quality and ensure protection and healthy work conditions for all personnel.

- Remove nuisance odour to improve air quality for personnel and neighbouring companies and residential areas.

- Remove corrosive gases to protect equipment and ensure safe and stable production.

- Quickly reduce hydrogen peroxide (H2O2) toxicity levels following decontamination to enable faster cleanroom recovery, saving valuable downtime and money.

- Help your facility comply with industry guidelines and regulations.

Camfil Molecular Filtration for Life Science Applications

Global clean air solutions manufacturer Camfil offer a complete range filtration solutions designed to improve indoor air quality through the removal of ultrafine airborne particulates, VOCs and toxic, hazardous, corrosive or odourous gases.

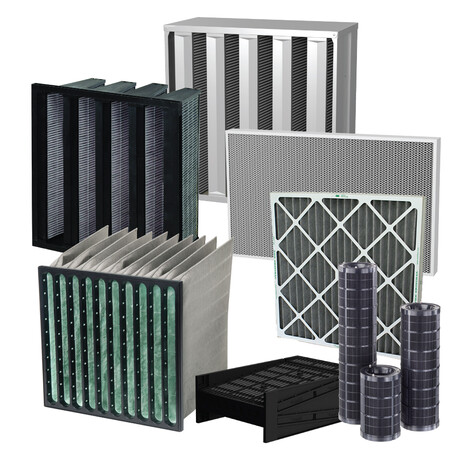

Camfil offer a variety of molecular filtration solutions to support life science cleanroom applications, including:

- Combination particle and molecular air filters designed for HVAC applications

- High efficiency, compact style molecular air filters for cleanroom AHUs and housings

- High efficiency panel style molecular air filters for cleanroom ceilings

- Deep bed molecular filtration housings for exhaust air applications

- Activated carbon, activated alumina and custom blended media for molecular air filter housings

- ProSafe CC 6000 mobile air cleaner with particulate filtration using Camfil Absolute™ HEPA filters or E11 rated filters and molecular filtration using activated carbon or custom gaseous filtration options. Camfil ProSafe products conform to BRCGS standards for food safety to help food and pharmaceutical processing facilities comply with stringent industry standards on safety, traceability and control.

For more information regarding our range of molecular filters, please go to https://www.camfil.com/en-au/products/molecular-filters.

Burkert Microsensors: Precision and Partnership for Critical Laboratory and Medical Applications

Burkert microsensors are engineered for seamless integration into laboratory and medical devices,...

Safeguarding Cryopreservation: When Failure Is Not an Option

Vaisala's viewLinc Continuous Monitoring System was developed with high-stakes applications...

World First — Clever Engineering and Flexible Technology Solves a Nanoparticle Challenge

It is not every day that you get to solve a unique problem. But that's exactly what happened...