Spinifex condoms — thinner than a human hair

The secret to the world’s thinnest, strongest latex condoms and surgical gloves may lie in the resin from spinifex grass, which the Indjalandji-Dhidhanu people of the Camooweal region in north-west Queensland have long used to attach spearheads to their wooden shafts.

A team from The University of Queensland’s Australian Institute for Bioengineering and Nanotechnology (AIBN) has developed a way to extract nanocellulose from spinifex. This significantly improves the physical properties of water-based rubber latex, resulting in surgical gloves and condoms that are as thin as a human hair.

Professor Darren Martin describes the super-thin yet strong and supple result as the “Holy Grail for natural rubber”. The spinifex nanocellulose is a flexible nano-additive that makes a stronger, thinner membrane that retains flexibility and has so far outperformed traditional latex condoms in key volume and pressure tests.

Condom producers perform burst tests on production samples that inflate condoms while measuring volume and pressure. Latex manufactured with the new spinifex nanocellulose additive averaged a performance increase of 40% in volume and 20% in pressure.

Professor Martin believes that with further refinement, the spinifex latex can be made up to 30% thinner than the 45 microns achieved during its first commercial dipping run, which is about the width of a human hair.

The global latex market is worth billions annually and this new technology could be a boon for Indigenous communities in far-flung areas where the native grass grows.

UniQuest, the commercialisation company of UQ, has signed an agreement with the Dugalunji Aboriginal Corporation (DAC) recognising the contribution of the traditional owners’ knowledge in this development and ensuring an ongoing role in the new business. It is hoped that spinifex harvesting and processing will provide future opportunities for the Indigenous population across the remote areas where spinifex thrives, according to DAC Managing Director Colin Saltmere.

“We’re very excited by the prospects of commercialising the technology to provide an entirely new industry to regional Australia,” Saltmere said.

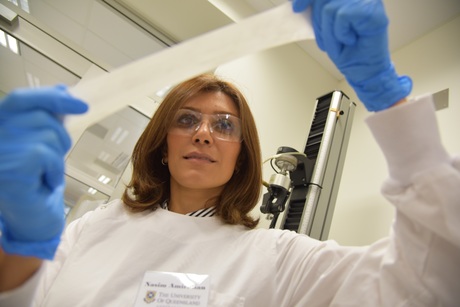

The processing of spinifex into nanocellulose is relatively straightforward, according to AIBN’s Dr Nasim Amiralian. The spinifex is hedged, chopped and pulped with sodium hydroxide, similar to paper pulp. It is then forced through a very small hole under mechanical pressure, which peels the nanofibres away from the pulp and results in nanocellulose suspended in water. At this stage, it is ready to add to water-based rubber latex.

UQ Vice-Chancellor and President Professor Peter Høj said the spinifex nanocellulose project is a prime example of the UQ research philosophy to create tangible solutions effecting positive change, engineering next-generation products while generating funding for future innovation.

“This completes the laboratory-to-market life cycle that can deliver benefits to millions, taking excellence to what we call Excellence Plus, and through that we aim to create change,” Professor Høj said.

Mini lung organoids could help test new treatments

Scientists have developed a simple method for automated the manufacturing of lung organoids...

Clogged 'drains' in the brain an early sign of Alzheimer’s

'Drains' in the brain, responsible for clearing toxic waste in the organ, tend to get...

World's oldest known RNA extracted from woolly mammoth

The RNA sequences are understood to be the oldest ever recovered, coming from mammoth tissue...