3D printing helps customise N95 respirators for a better fit

Medical experts at Flinders University have developed a low-cost way to customise N95 filtering facepiece respirators (FFRs) for health workers working on the frontline of the pandemic. The researchers say the decrease in ‘leakage’ and greater comfort for the wearer could also have applications to improving respirator and mask safety in a wide range of industrial settings in health care and beyond.

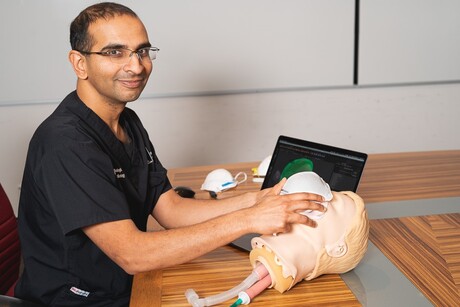

Working with public hospital workers during the COVID-19 pandemic, cardiology research fellow Darius Chapman and cardiac electrophysiology scientist Professor Anand Ganesan led a project to compare the performance of personalised 3D-printed frames to improve N95 FFRs test scores compared to regular respirators. The results were published in the Journal of Occupational and Environmental Hygiene.

The researchers used a mobile iPhone camera and an app to produce 3D scans of volunteers’ faces, which were then imported into a software program to define each user’s facial structure and features to scale. A plastic and then silicone-coated frame was then made with a commercially available 3D printer from these individual facial impressions, or virtual scaffolds.

“Overall, the quantitative fit testing significantly improved, as did the respirator comfort and tolerability factor,” Chapman said.

Ganesan added, “With further refinement, this system could considerably advance the correct fitting of N95 and other FFRs, which have become increasingly important in our healthcare systems during the pandemic.

“The ability to generate the low-cost, 3D-printed mesh from a readily available mobile device technology means that individual face scans can be easily and cost-effectively generated around the world in any location.”

According to Chapman, individually and anatomically personalised 3D-printed face frames represent a rapidly scalable technology to improve healthcare worker protection and comfort. Ganesan added, “A proposed workflow for this technology could involve the scans being sent direct to fabrication centres which could be located at a distance from hospitals or other health facilities.

“Further, using readily available, consumer-grade 3D printers and materials at low cost could be an important practical advance to decreasing leakage from N95 FFRs in workers as well as other people at high risk of severe outcomes from respiratory virus, like immunocompromised people.”

Antibody treatment reprograms immune system after heart attack

A new drug being trialled in heart attack patients could reprogram the immune system to prevent...

Nanoparticles supercharge vinegar's wound-healing power

Adding microscopic particles to vinegar can make them more effective against dangerous bacterial...

Not all brown snake venoms are alike, causing antivenom concerns

Venom from northern and southern populations of eastern brown snake builds blood clots in very...