Recyclable nano-filter for face masks developed

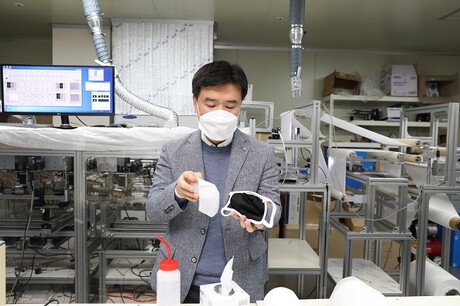

Researchers from the Korea Advanced Institute of Science and Technology (KAIST) have developed a nano-filter that maintains excellent filtering efficiency, even after handwashing, through the development of proprietary technology that aligns nanofibres with a diameter of 100–500 nm in orthogonal or unidirectional directions.

Re-usable, nano-filtered face masks could help to relieve the challenges arising from South Korea’s supply shortage of face masks due to the COVID-19 pandemic. The face masks most commonly used in the country are disposable ones, originally made for filtering out up to 94 or 95% of fine dust, referred to as N94 or N95 masks.

Professor Il-Doo Kim and colleagues used an insulation block electrospinning process to manufacture orthogonal nanofibres by controlling the alignment of nanofibres. This structure can minimise delivering of the pressure towards the air filter and maximise the filtration efficiency, which is different from existing disposable masks without nanofibres.

Existing masks also fail to maintain their air filtering function because their electrostatic function disappears when exposed to water. Thus, their filtering efficiency is reduced significantly, making it almost impossible to re-use them. Prof Kim’s nanofibre design was proven to be water resistant with more than 94% filtering efficiency in 20 repeated bactericidal tests with ethanol. The nanofibre mask also showed no deformation in its nano-membrane structure despite the 20 handwashes. In particular, it was confirmed that there were no deformations in the membrane, even after soaking in ethanol more than three hours.

“We believe that this mask can be re-usable for about a month even after washing in ethanol,” Prof Kim said. “The inner filter can also be replaced.

“We found that the mask filters out up to 80% of 600 nm particles even after undergoing a bending test more than 4000 times.”

Prof Kim’s recently established start-up company, the Kim Il-Doo Research Institute, can currently produce 1500 nanofibre filters per day. He is now awaiting final approval from the Ministry of Food and Drug Safety to bring his product into the market.

Please follow us and share on Twitter and Facebook. You can also subscribe for FREE to our weekly newsletters and bimonthly magazine.

Nanofibre uniform protects soldiers against chemical threats

A next-generation uniform prototype employs nanofibres to safeguard wearers from chemical and...

Monoclonal antibody shows protection against COVID variants

A monoclonal antibody appears effective at neutralising the numerous variants of SARS-CoV-2, as...

New catalyst enhances efficiency of ammonia conversion

The catalyst has the ability to enhance the efficiency of ammonia conversion, which could improve...