'Catalytic condenser' gives metal chameleonic properties

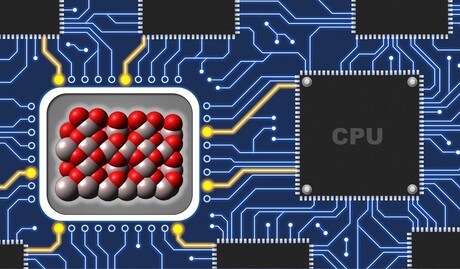

US energy researchers, led by the University of Minnesota Twin Cities, have invented a groundbreaking device that electronically converts one metal into behaving like another to use as a catalyst for speeding up chemical reactions.

The fabricated device, called a ‘catalytic condenser’, demonstrates that alternative materials that are electronically modified to provide new properties can yield faster, more efficient chemical processing. It has been described in the journal JACS Au.

Chemical processing for the last century has relied on the use of specific materials to promote the manufacturing of chemicals and materials we use in our everyday lives. Many of these materials, such as precious metals ruthenium, platinum, rhodium and palladium, have unique electronic surface properties. They can act as both metals and metal oxides, making them critical for controlling chemical reactions. These expensive materials are often in short supply around the world and have become a major barrier to advancing technology.

In order to develop their method for tuning the catalytic properties of alternative materials, the researchers relied on their knowledge of how electrons behave at surfaces. The team successfully tested a theory that adding and removing electrons to one material could turn the metal oxide into something that mimicked the properties of another.

“Atoms really do not want to change their number of electrons, but we invented the catalytic condenser device that allows us to tune the number of electrons at the surface of the catalyst,” said Minnesota’s Professor Paul Dauenhauer, who led the research team. “This opens up an entirely new opportunity for controlling chemistry and making abundant materials act like precious materials.”

The catalytic condenser device uses a combination of nanometre films to move and stabilise electrons at the surface of the catalyst. This design has the mechanism of combining metals and metal oxides with graphene to enable fast electron flow with surfaces that are tuneable for chemistry.

“Using various thin film technologies, we combined a nanoscale film of alumina made from low-cost abundant aluminium metal with graphene, which we were then able to tune to take on the properties of other materials,” said Tzia Ming Onn, a postdoctoral researcher at Minnesota. “The substantial ability to tune the catalytic and electronic properties of the catalyst exceeded our expectations.”

The catalytic condenser design has broad utility as a platform device for a range of manufacturing applications. This versatility comes from its nanometre fabrication that incorporates graphene as an enabling component of the active surface layer. The power of the device to stabilise electrons (or the absence of electrons called ‘holes’) is tuneable with varying composition of a strongly insulating internal layer. The device’s active layer also can incorporate any base catalyst material with additional additives, which can then be tuned to achieve the properties of expensive catalytic materials.

“We view the catalytic condenser as a platform technology that can be implemented across a host of manufacturing applications,” said team member Dan Frisbie, also from Minnesota. “The core design insights and novel components can be modified to almost any chemistry we can imagine.”

The team plans to continue their research on catalytic condensers by applying it to precious metals for important sustainability and environmental problems. With financial support from the US Department of Energy and National Science Foundation, several parallel projects are already in progress to store renewable electricity as ammonia, manufacture the key molecules in renewable plastics and clean gaseous waste streams. The team is also working with the University of Minnesota Office of Technology Commercialization and has a provisional patent on the device.

Please follow us and share on Twitter and Facebook. You can also subscribe for FREE to our weekly newsletters and bimonthly magazine.

Widespread applications of shake flask off-gas analysis across biotechnology

Despite the emergence of more sophisticated bioreactor systems, shake flasks continue to play a...

Scientists may finally know what makes Mars red

The water-rich iron mineral ferrihydrite may be the main culprit behind Mars's reddish dust,...

Novel fluidic processor offers switchable capture and release

It has been a longstanding challenge to design a platform that enables the switchable capture and...